Pipeline Integrity Digital Twin Platform

The only pipeline integrity digital twin built for the complete asset lifecycle. Unite design, ILI, CP, survey and operations data into automated assessments that update when new data arrives with no waiting for reports.

Trusted by Leading Pipeline Operators

Managing integrity across subsea and onshore assets where safety and compliance are non-negotiable

Stop Chasing Data. Start Making Decisions.

A systematic pipeline that transforms raw integrity datasets into real-time insights that are automated, repeatable, and audit-ready.

Ingest

Centralise design drawings, ILI reports, CP surveys, operations logs and inspection records. No scattered folders. No vendor wait times.

Automate

Turn complexity into clarity. Automated fitness-for-service assessments flag critical threats instantly, available 24/7.

Update

Same-day results when new data arrives. Upload fresh ILI data, re-run assessments immediately and get management reports the same day.

Optimise

Target what matters. Predictive analytics identify high-risk segments so you reduce inspection waste and focus spend on real threats.

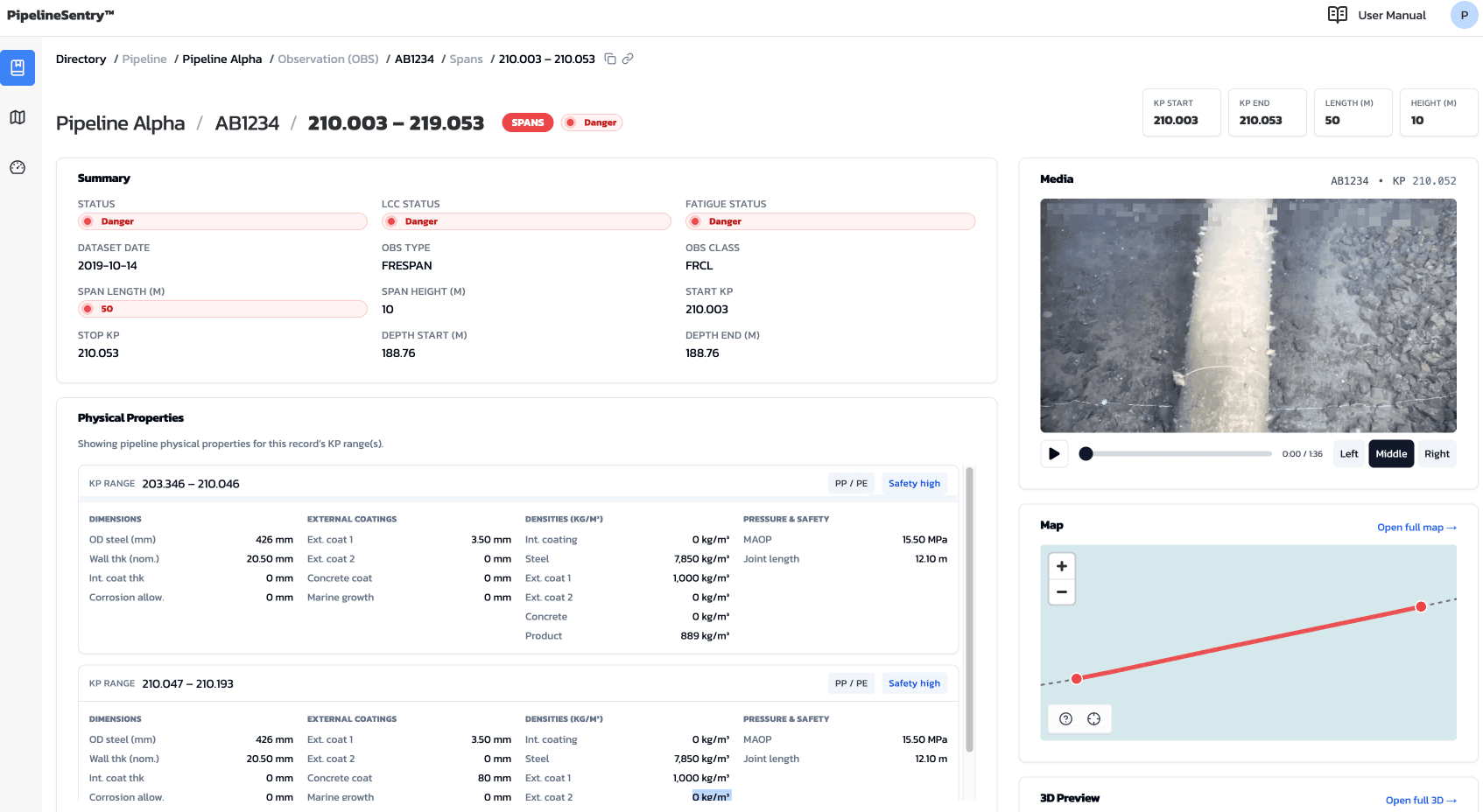

Engineering-Grade KP Alignment

One spatial truth for all pipeline data — aligned to centimetre-level accuracy

Unified spatial reference

Internal inspection data, external surveys, and operational observations resolved to a common kilometre point (KP), creating a single spatial model where internal condition, external environment, and pipeline geometry are analysed together.

Multi-source correlation

Metal loss, deformation, and anomalies directly related to seabed interaction, free spans, crossings, material strength, and environmental exposure. Historical comparison and corrosion growth tracking becomes routine.

Synchronised visual evidence

ROV and drone video, imagery, and sensor streams time- and position-aligned to KP. Visual context for every inspection point, with no ambiguity or post-processing guesswork.

Analysed together, not reconciled later

Internal condition, external environment, and pipeline geometry in one model — no approximation, no post-processing alignment.

Engineering decisions, not visual estimates

Centimetre-level precision enables fitness-for-service calculations, anomaly rectification, and ILI validation workflows.

Automated with confidence

Consistent spatial relationships enable repeatable integrity assessments. Same methodology, same standards, every time.

Track change over time, not snapshots

Historical anomaly comparison and corrosion growth rate analysis across inspection campaigns. Time-to-failure assessments built on actual data.

Common Questions

Everything you need to know about PipelineSentry

Your Integrity Data is Ready. Let's Put It to Work.

Pipeline operators are eliminating weeks of report wait times and cutting inspection waste with automated, same-day assessments. Join them. Share your current workflow and we'll show you exactly how PipelineSentry transforms your integrity management, from data chaos to decision clarity.